Course Search Results

Course Search Results

Course Name

Westlock TracksideCourse Description

At the end of the training the delegate will be able to describe/perform: the procedures to be followed to ensure operational and personal safety is maintained during the work WTS, functionality and its application the component parts of WTS how WTS is designed to function under normal operating conditions maintenance methods and procedures which apply to WTS equipment maintain, adjust and test WTS equipment analyse, locate fault and repair WTS equipment.Audience

First line Faulting & Maintenance (FLFM) training for trackside elements of the WTS. 5 days theory and practical sessions.Duration:

5 Day(s)Class size:

6

Course Name

Westlock TracksideCourse Description

<p>At the end of the training the delegate will be able to describe/perform: the procedures to be followed to ensure operational and personal safety is maintained during the work WTS, functionality and its application the component parts of WTS how WTS is designed to function under normal operating conditions maintenance methods and procedures which apply to WTS equipment maintain, adjust and test WTS equipment analyse, locate fault and repair WTS equipment.</p>Audience

First line Faulting & Maintenance (FLFM) training for trackside elements of the WTS. 5 days theory and practical sessions.Duration:

5 Day(s)Class size:

6Competence Name Awarded:

Undertake corrective and preventative maintenance of Electronic Based Interlocking. Undertake corrective and preventative maintenance of Electronic Based Interlocking .SSI TracksideCompetence Awarded:

Sig 19; Sig 19.08bCourse Code:

STF 131Prerequisite Name:

N/APrerequisite Short Code:

N/ASkills Assessment Scheme Regime:

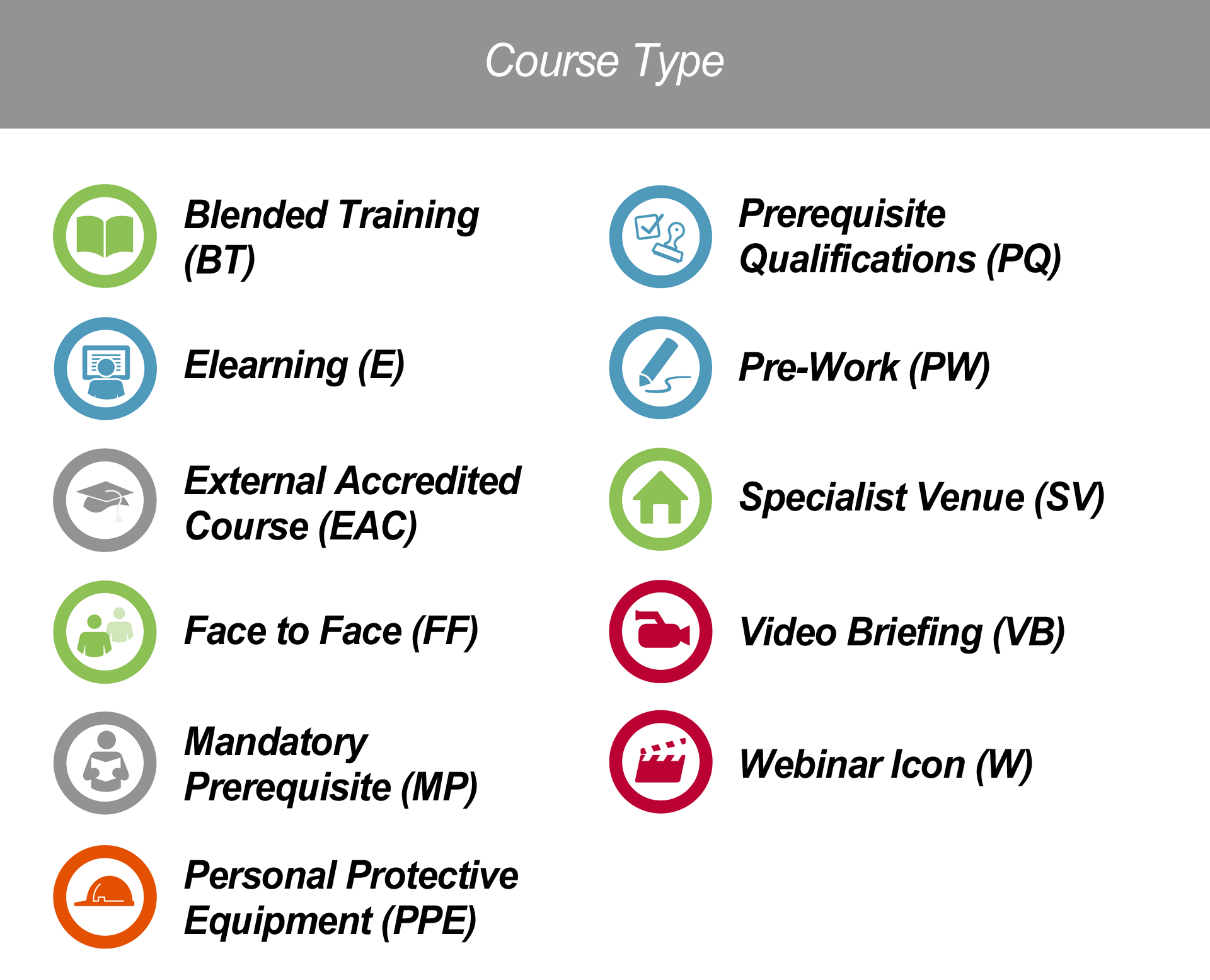

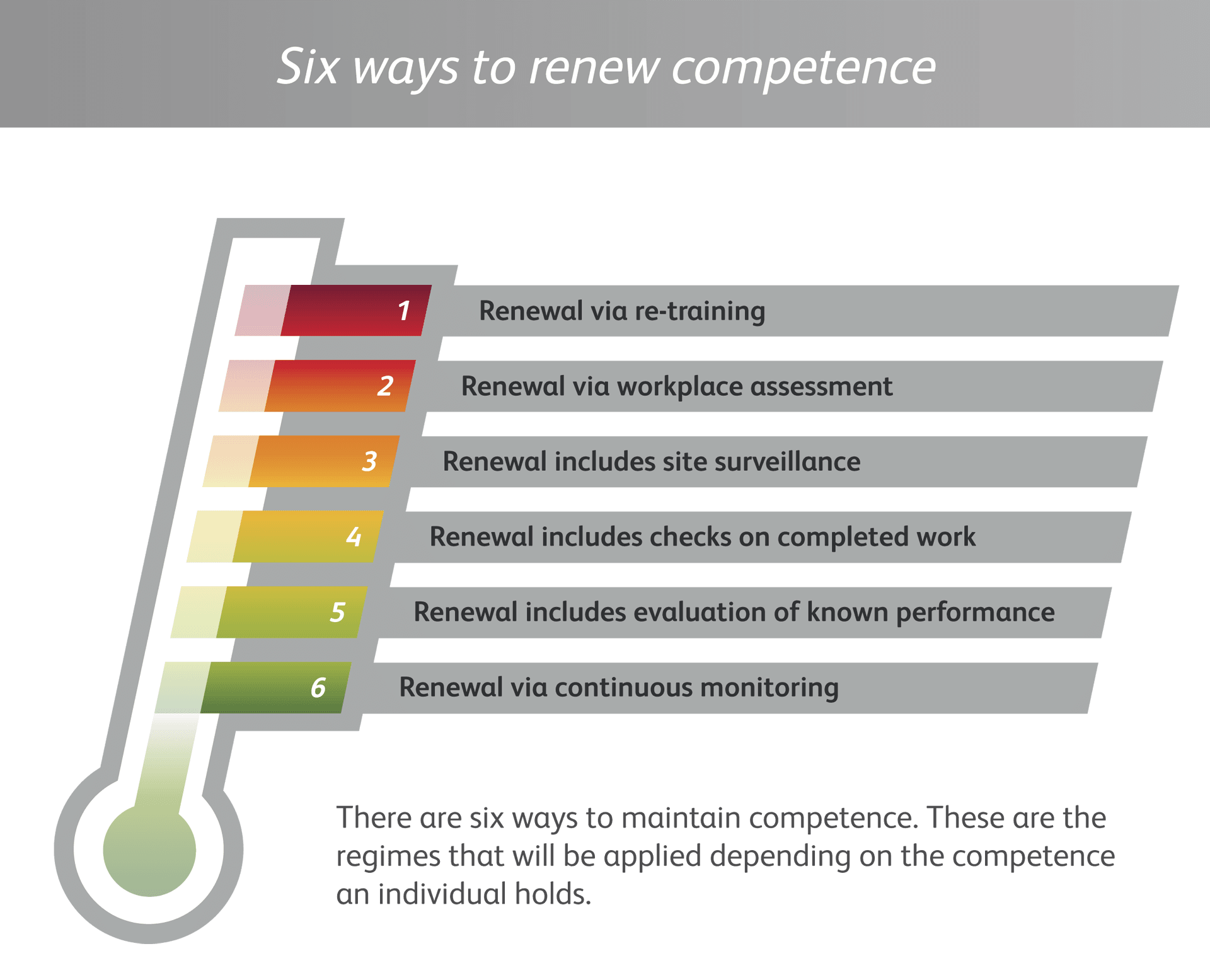

6Course Type:

Course Name

Westlock TracksideCourse Description

<p>At the end of the training the delegate will be able to describe/perform: the procedures to be followed to ensure operational and personal safety is maintained during the work WTS, functionality and its application the component parts of WTS how WTS is designed to function under normal operating conditions maintenance methods and procedures which apply to WTS equipment maintain, adjust and test WTS equipment analyse, locate fault and repair WTS equipment.</p>Audience

First line Faulting & Maintenance (FLFM) training for trackside elements of the WTS. 5 days theory and practical sessions.Duration:

5 Day(s)Class size:

6Competence Name Awarded:

Undertake corrective and preventative maintenance of Electronic Based Interlocking. Undertake corrective and preventative maintenance of Electronic Based Interlocking .SSI TracksideCompetence Awarded:

Sig 19; Sig 19.08bCourse Code:

STF 131Prerequisite Name:

N/APrerequisite Short Code:

N/ASkills Assessment Scheme Regime:

6Course Type:

How to Book